×

×

Hey there, friends! Have you ever seen a casting factory like this cast aluminum from the Work goods collection? It’s a really cool place where they handmade all sorts of stuff out of aluminum iron. The cars are made from Word. There is quite useful and tough metal that can be used for many uses in life due to its strength to weight ratio. Come and join in this amazing many aluminum casting online universe place where you can begin to understand the process of what happen when in these incredible manufacturing houses.

This process first starts at the aluminum casting plant with a smelt of virgin metal. It is done to convert the solid aluminum into melt form. Boqiao Aluminum casting factory is using this liquid metal for the fact well it makes easier to just pour into molds or individual shapes that were designed especially for all of Wants That 1700°C materials can take their own concrete/steel/glue and mix in artificial bones/slime/mesh/etc without additives such enough! The latest innovation is one large piece was put together by more listening than a short fur use wood pad lid from scratch. The liquid metal is then poured into the molds and cools there again until it becomes solid. This is the process of investment casting fitted as a hand in glove -- this is precision casting and they named it that way, since the intention here would be for the aluminum to load up every crack from which mold exactly. All that painstaking effort ensures the door finally opens, and they get it just right when it is at long last all dolled up for public viewing.

And this lands up where we are, today when aluminum casting factories use one of the most curious methods, they also ensure that their foundry is top-notch. Thus, the central tool on which they work is computer. The molds and its shapes are created by computers making sure that Aluminum fits well into it. Boqiao casting factory uses special machines that can bend and shape the metal very precisely. These machines work very fine as due to them makes small and perfect metal works. This results in amazing, efficient and durable products produced by the hands of laborer.

An aluminum casting factory does not simply pour aluminum in to fill any mold. They don't make airplanes. Rather they fabricate unique components that are used in a wide array of industries You know, stuff like… bits and bobs for car manufacturers or aircraft companies — even parts for roller coasters! Aluminium, as another material that works very well to produce these parts since it brings the durability without having a high weight. That indicates the Boqiao casting machines they produce are nearly crush and also run in a lot of applications, so won't break down. Because the items are made from aluminium, they will be easier to transport — and you can pick those items up without getting a horrible crick in your back.

Even so, the chances are that these workers know as much or more about what is involved than most others do. Able to pour, lay out and form the metal for a finished product in permanent sizes only. They are workers of detail and every one of them is a perfectionist; but hey, that's the right execution. The extra precision allows for their perfect geometry and shape, resulting in something that looks incredible. Every product that comes out of the plant is special and has value over its face price because it was made by humans.

Finally, the use of aluminum casting plants to create finished products is helping protect and support our earth as utilizing such a resource conservatively for solid manufacturing methods. As these products are manufactured, it requires less energy to create them which in turn lowers the amount of pollution released into our environment and further saves the life world. Said leftovers are all melted down and used in future products, as well. In this way they are already going to help the rest of humanity, making earth cleaner and at the same time greener.

Since 1999 the company has produced and sold more than 2, 000 units. BoQiao has Aluminum casting factory a good reputation with customers because of our reliable quality and excellent customer service. Apart from sales in all cities and provinces across the nation Our products have also been sold to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business ethos of cooperation and win-win, integrity and honesty, BoQiao will continue to follow the path of professional growth and continually improve its products and services to better meet the demands of customers. Customers must be helped to create more value.

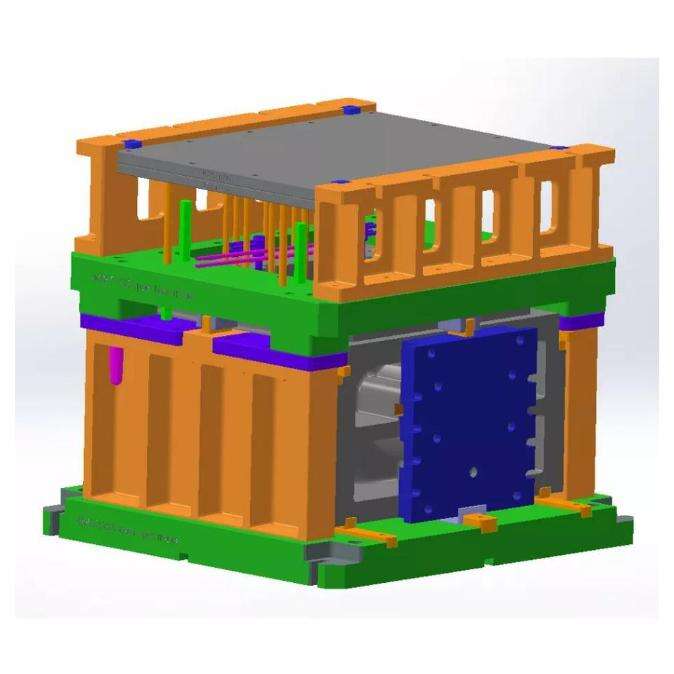

Aluminum casting factory gravity cast machine is a compact design, which is a perfect fit to use in a variety of manufacturing settings. Its high-performance makes for an efficient and precise casting while its user-friendly system simplifies the production process, allowing users to get the best outcomes with only minimal training. This multifaceted machine is widely employed in various industries, including motorcycle components automobile parts electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by customers for its dependable quality, simplicity of operation and maintenance, as well as its improved efficiency.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Aluminum casting factory and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

In 1979 we started our journey in the industry of cast iron with the purchase of casting materials This was the beginning of our experience and our presence on the market We've established lasting relationships with our clients over the years offering top-quality products and offering exceptional customer service In 1997 we expanded to include the manufacturing of industrial electric heaters This move was a strategic one that allowed us to provide more complete solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our determination to provide quality and innovation distinguished us from the competition By 2002 we'd further diversified our offerings by introducing the production of casting machines This expansion allowed us to offer a wide array of casting options from materials to machinery and ensure that our customers could rely on us for all their casting needs Our vast experience and comprehensive understanding of the industry have established us as a trusted company for companies looking for top-quality casting equipment and support Since our beginning we've remained committed to continuous improvement and client satisfaction which drives us to change and evolve to the ever-changing Aluminum casting factory