×

×

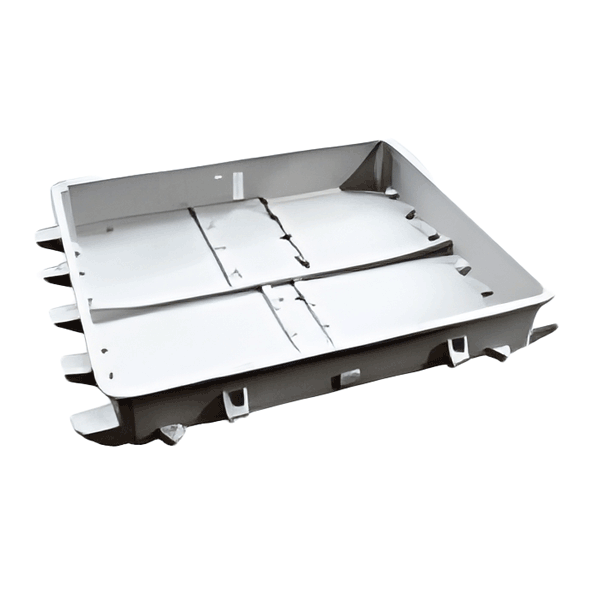

Daar is ook 'n bouproses vir motors en trucke engines. In eenvoudige terme is die deel wat "motorblok" genoem word een lewensbelangrike element onder motorkomponente. Die motorblok is wat werklik alles belangrik saamhou en die organ in funksie hou. Een van die maniere waarop hierdie materiaal dikwels vervaardig word, is om 'n sand casting metode te gebruik. Deur 'n sand casting vorm te gebruik, word heet vloeibare metaal in die holte van 'n aluminium foundry gegooi. Die sand vorm van Produkte van Boqiao verwyder nadat die koeling van metaal primitief. Dit bring een stuk metaal wat Mould gevorm het.

Alles het goeie en slegte punte, veral in terme van die gebruik van sandgiet om motorkusse te produseer. Die beste van hierdie proses is dat dit selfs nie baie kos nie. Dit is omdat sand goedkoop verkrybaar is en hergebruik kan word nadat dit een keer gebruik is. Sandgiet kan ook tamelyk kunstig wees. Met sandvorms kan jy byna enige vorm of gestalte skep wat in jou gees kom. Maar, daar is ook enkele nadele. Byvoorbeeld, dit is moeilik om die oppervlak van die metaal glad te kry in die geval van sandgiet. Snywye: In die metaal is daar soms lugbobbels wat binne ingesluit word en hulle kan swaktes in sterkte en voorkoms veroorsaak, so kies vir Gravitasie drukgiet masjiene van Boqiao.

Die sandvorms speel 'n lewendige rol en is die regte keuse in die bou van motorkusse. Feitlik gesproke is 'n sandvorm net 'n ledige ruimte in die sand wat in die vorm van gesmeltde metaal gemaak is. Die proses van die vorming van 'n sandvorm begin met die skepping van 'n patroon. Dit is 'n identieke vorm en grootte soos dié wat geproduseer moet word, so kies vir Laagdruk drukgiet masjiene van Boqiao. Wanneer die patroon voltooi is, word dit in 'n doos gevul met sand gesit en dan vasgedruk sodat die patroon sy vorm kan hou. Hierdie patroon word dan voorzichtig verwyder om sy vorm in die sand agter te laat. Die heet metaal word dan in hierdie ruimte gegooi, dit vullend en die vorm van die vorm aannemend.

Daar is 'n paar dinge wat jy moontlik wil oorweeg, as sandgiet sal werk nie fyn nie. Byvoorbeeld, eerste en voormal is die tipe sand wat jy gebruik. Die sand moet weerstand bied teen die hoë hitte van smeltemaal, so word spesifieke tipes sands wat vir hierdie doel bekwaam is dikwels gebruik. 'n Ander oorweging is die gewig en vorm van die deel wat vervaardig word. Die deel, wanneer meer intrikate vorms daarin gemaak word, sal spesiale vorme vereis en veel moeiliker wees om perfek spesifikasies te skep. Soosook, is dit ewe belangrik om die temperatuur van die metaal wat gegooi word te reguleer en die invoer tempo is ook waargeneem sodat opt vir BQ smelttoestel .

Verskeie tegnieke en beste praktiese metodes wat beter kwaliteit产出 lewer deur skapegieting te gebruik, kan met 'n aardgas-toorn gesmelt word. Dit kan help om die aantal deeltjies en verontreinigers op hierdie metaal te verminder, wat dit sterker en skoner maak. Dit is ook 'n goeie idee om 'n vakuumstelsel te gebruik om al die lugbellen of gevangen gase in die gietvorm te verwyder. Dit maak die metaal selfs sterker en verminder gebreke. Verder word hierdie skapemalle ook aluminium gietdele bedek met spesiale materiaalle vir 'n gladser oppervlak, wat verdere die kans op foute verminder. Verseker jouself ook om die malle baie goed te skuif tussen die gebruik. Dit verseker dat hulle volkome skoon is van stof, slym of enige ander onwenslike stowwe.

Ons maatskappy het sedert 1999 meer as een motorblok-sandgieteenhede verkoop en vervaardig. Uitstekende diens en betroubare gehalte het vir ons maatskappy 'n goeie reputasie by sy kliënte besorg. Die maatskappy het sy produkte na Suid-Oos-Asië, Afrika, Suid-Amerika sowel as die Midde-Ooste uitgevoer. Kliënte was ook tevrede met die diens en gehalte. Kliënte moet aangemoedig word om meer waarde te skep.

Nanjing BoQiao Machinery Co., Ltd is 'n professionele ontwerp-, vervaardigings- en verkoopvervaardiger van verskeie gietmasjiene, hittebehandelingsuitrusting en industriële oonde. Bestaande produkte, insluitend swaartekraggietmasjiene, lae-druk-gietmasjiene, smeltovne, gloei-ovne, skielikekoelovne, ouingsovne en dwars-magnetiese oonde, asook ander produkte, het 18 tipes en byna 100 verskillende produkspesifikasies gevorm. Ons bied 'n reeks sleutel-in-die-hand-oplossings aan wat tegniese advies, toerustingkiesing en -vervaardiging sowel as prosesontwerp, asook opvoeding en bedryfsopleiding insluit. Ons is oortuig dat ons produkte waarde vir ons kliënte sal skep. Produkte word wyd gebruik in: elektriese kragbeskermingsmateriaal, motorfietsonderdele, motoronderdele, nuwe energie, elektroniese en elektriese toestelle, hoë-voltaasje-skerms, ingenieursmasjinerie, ruimtevaartgietstukke, ventilators, enjinblok-sandgietstukke sowel as ander professionele gietstukproduksieondernemings.

BoQiao se swaartekastingmasjien het klein afmetings, wat dit 'n uitstekende keuse maak vir 'n verskeidenheid sandgietwerk van enjinblokke. Die BoQiao swaartegietmasjien se kompakte ontwerp en hoë prestasie maak dit 'n ideale keuse vir verskeie vervaardigingsomgewings. Sy betroubaarheid en waarde maak dit 'n waardevolle belegging vir maatskappye wat na betroubare gietoplossings soek. Dit word deur kliente geprys vir sy konsekwente gehalte, maklike bedryf en onderhoud, sowel as verhoogde produktiwiteit.

Ons reis na die gebied van gietwerk het in 1979 begin met die verkoop van gietmateriale wat die grondslag vir ons ervaring sowel as ons markposisie gelê het. Oor die jare het ons langdurige verhoudings met ons kliënte opgebou deur hoëgehante produkte en uitstekende dienste aan te bied. In 1997 het ons ons dienste uitgebrei om die vervaardiging van elektriese oonde vir nywerheidsgebruik in te sluit. Hierdie stap was strategies en het ons in staat gestel om meer volledige oplossings vir ons kliënte aan te bied en hul toenemende vraag na hoëgehante, betroubare verhittingsuitrusing te bevredig. Op hierdie stadium het ons toewyding aan gehalte en innoverende denke ons van die mededinging laat uitstaan. In die sandgietwerk van enjinblokke het ons verdere uitbreiding onderneem na die vervaardiging van gietmasjiene. Ons kon die volledige spektrum van gietoplossings verskaf, insluitend beide die materiale sowel as die masjinerie. Dit het ons in staat gestel om ’n eenstopwinkel vir ons kliënte met gietbehoeftes te word. Ons ervaring en uitgebreide kennis van die bedryf het ons ’n betroubare vennoot vir besighede wat na eersteklas gietuitrusing en -diens soek, gemaak. Ons het altyd toegewy aan kliëntetevredenheid en voortdurende vooruitgang gewees. Dit het ons gedryf om te ontwikkel en aan te pas in ’n mark wat voortdurend verander.