×

×

Key attributes

Other attributes

| Place of Origin | Jiangsu,China |

| Machine Type | Low pressure casting machine |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Core Components | PLC,Motor |

| Warranty | One Year |

| Key Selling Points | Famous brand PLC |

| Showroom Location | Egypt, India |

| Applicable Industries | Manufacturing Plant |

| Weight (KG) | 15000 |

| Condition | New |

| Brand Name | BOQIAO |

| Voltage | 380V |

| Power | 60.5kw |

| Dimension(L*W*H) | 5850·4155*5365 working size |

| Product name | Low pressure casting machine for car aluminumwheel rim |

| Application | Aluminium Casting Industry |

| Mold | Permanent or sand mold |

| Capacity | 600kg |

| After Warranty Service | Repair Service |

| Cooling system | Water or air cooling |

| Certification | CE and ISO 9001/2015 |

Packaging and delivery

| Selling Units: | Single item |

| Single package size: | 200X200x300 cm |

| Single gross weight: | 15000.000kg |

Product descriptions from the supplier

Overview

Products Description

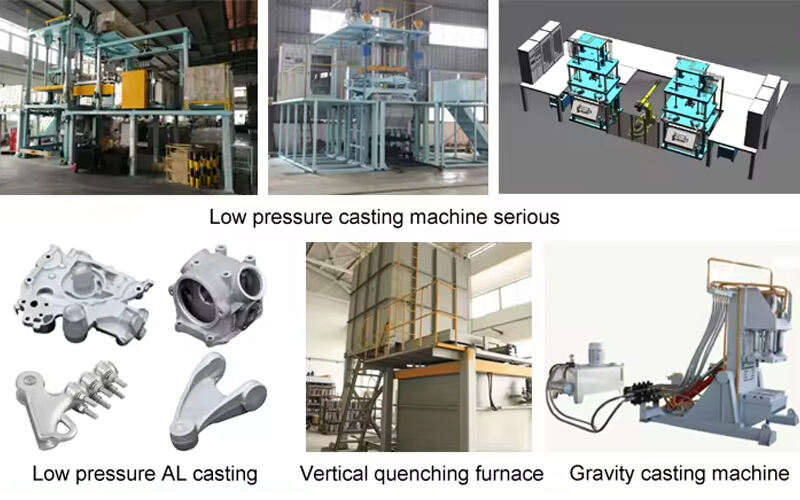

Low Pressure Casting Machine for Aluminum Casting

Low pressure casting technology is a special casting pricess which mainly is used on producing aluminum casting. The principle of low pressure casting is to push the aluminum liquid in the holding furnace into the metal mold by compressed air. And the aluminum liquid is solidificated in the mold under certain pressure. Compared with other traditional special casting method, low pressure casting process has many abvious advantages:mechanical parameter is over 30% than gravity casting; The casting has no riser and the pouring gate is very small; Easy to operate and high automation and low lobar indensity and so

Product Paramenters

| Standard Low Pressure Casting Machine Technology Specification | ||||

| Parameter | Unit | J453L | J455L | J458L |

| Machine body | ||||

| Fixed columns clearance | mm | 1050*750 | 1400*1000 | 1750*1250 |

| Distance between mobile and fixed platen | mm | 450-900 | 500-1350 | 550-1650 |

| Single side cylinder stroke | mm | 200 | 200 | 250 |

| Opening force of upper cylinder | KN | 122 | 177 | 245 |

| Closing force of upper cylinder | KN | 94 | 138 | 305 |

| Opening force of side cylinder | KN | 59 | 94 | 165 |

| Closing force of side cylinder | KN | 78 | 122 | 212 |

| Ejection force | KN | 122 | 177 | 305 |

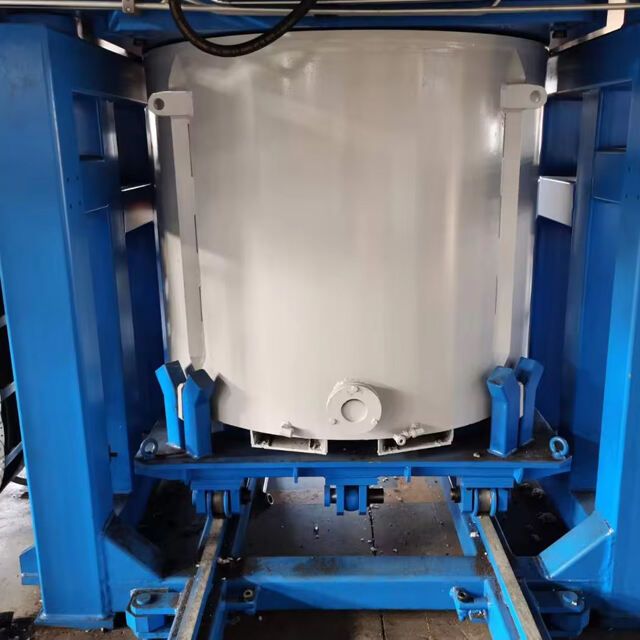

| Holding furnace | ||||

| Furnace type | crucible | Crucible or Refactory | ||

| Capacity | KG | 300 | 500 | 800 |

| Power rate | KW | 20 | 30 | 45 |

| Temperature control accuracy | ±℃ | 2 | 5 | |

| Furnace pressure | Bar | Max.1.5 bar | ||

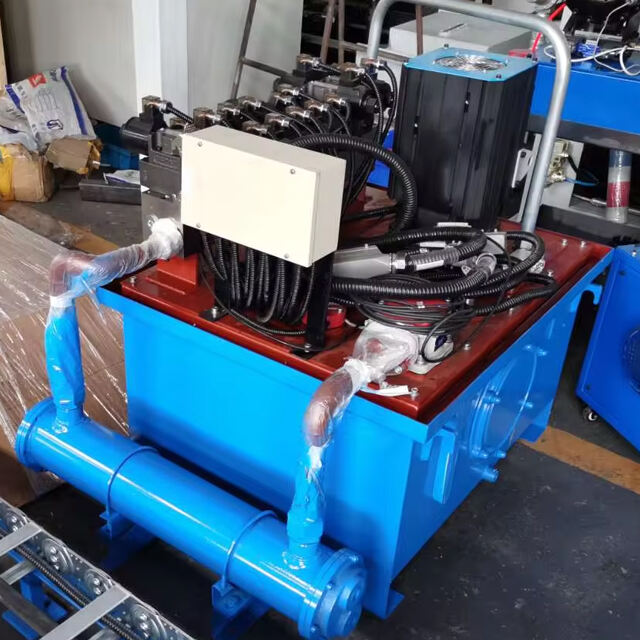

| Hydraulic pump station system | ||||

| Motor type (Regulation or Servo) | optional | |||

| Motor power rate | KW | 5.5 | 15 | 18.5 |

| Hydraulic pressure | Bar | Min. 80 bar -max.120 bar | ||

| Pump type (gear or plunger) | Optional | |||

| Cooling type | Air | Air orwater | Water | |

| Cooling water consumption | L/Min | 40 | 50 | |

| Operation control system | ||||

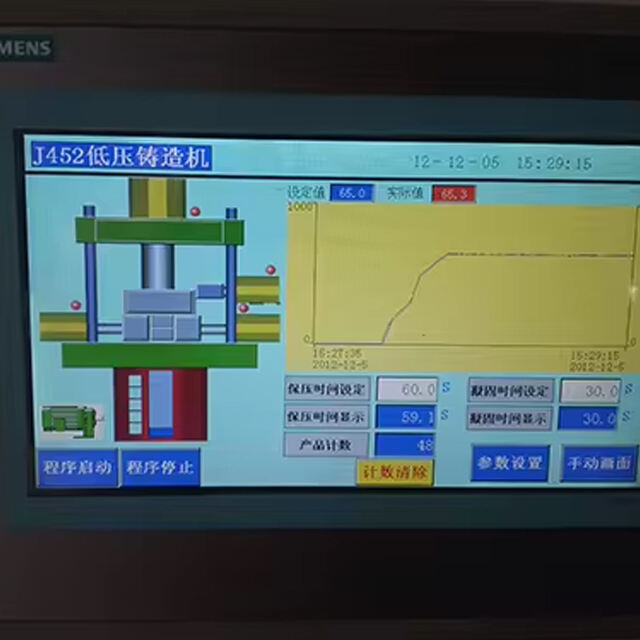

| PLC,HMI unit | Siemens | |||

| Operation method | Single circle automatic and semiautomatic | |||

| Main power voltage (380V 60HZ,400V 50HZ) | V,HZ | 380V 60HZ or 440V 50HZ | ||

| Auxiliary power voltage | V,HZ | 24 | ||

| Control cabinet cooling type | Fan | Fan or air conditioning | ||

| Cooling system | ||||

| Cooling medium | Water,air or water mist cooling | |||

| Flowmeter | Glass flowmeter or electric flowmeter | |||

| Control method | PLC control | |||

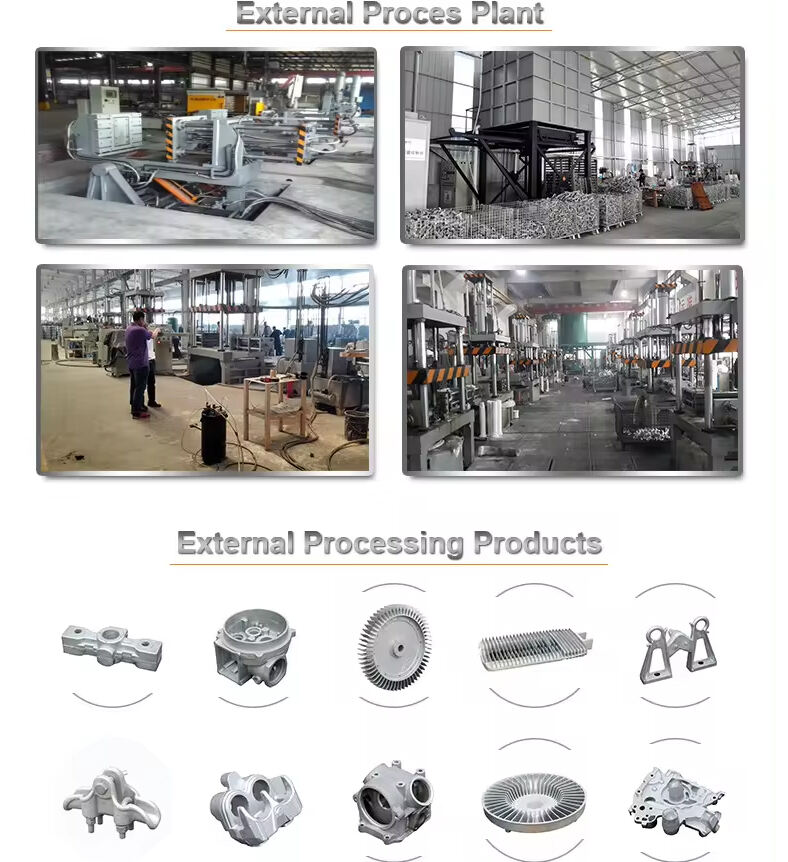

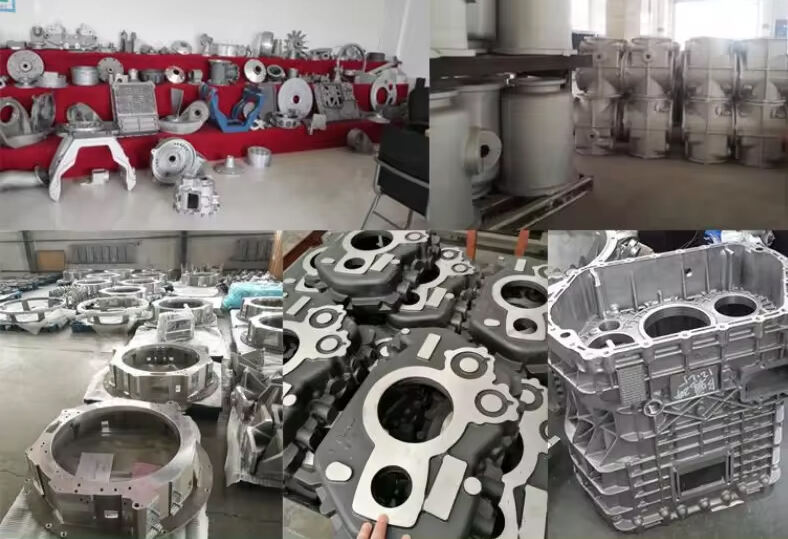

Details Images

Product features

Nonstick pan furnace material structure, effectively reduce oxidation burn loss

Fully digital servo hydraulic system, save energy over 50%

Full hydraulic drive, good stability

Siemens S7-1200+HMI automatic operation, SMC pneumatic control, high liquid surface pressure precision, stable operation system

Four guide post structure, high mold balance

Trolley reclaiming tray, be suitable for overweight casting reclaiming

Maybe You Like Our Other Equipment

Q:Are you manufacturer or trade company?

A:We are manufacturer

Q.What kind of products can be made with your machine?

A:Theoretically,our machine can produce the all aluminum casting with thickness over 4mm.But it is better to ensure after seeing

drawings or samples.

Q:How to ensure that we can produce qualified products by your machine?

A:The solution is that firstly we check your product drawing or samples.If the product is ok,you pay 50% of mold price,we make

mold for you.When the mold is made out,we try the mold and get the new samples.If the samples is qualified,you buy our machine.If

no,we pay back you the all money.

Q:What is your delivery time?

A:Commonly,we deliver within 60 days.

Q:Can i visit your factory?

A:Sure,welcome you.

Our address:Nanjing city,Jiangsu Province,China.

Nearest airport:Nanjing LuKou International Airport