Casting machines are one such tool that is an important part of making numerous things using melted material. These machines have seen their benefits in the hands of both individuals and industries who use them to create toys, automotive parts or even beautiful pieces of jewelry. We felt that even though casting machines are made by countless firms internationally, the cream of the provervbial crop amounts to basically 10 different manufacturer!

Photo by Quoc Toan Ngo on Unsplash Advantages of Casting Machines Efficient & Quick manufacturing: One of the main advantages that casting machines offer is their capacity to manufacture items effectively and promptly. This makes them an ideal purchase for both businesses and everyday consumers, as these machines are designed to last you a very long time while still allowing you the ability to create strong objects that will be performed over and over again without failing.

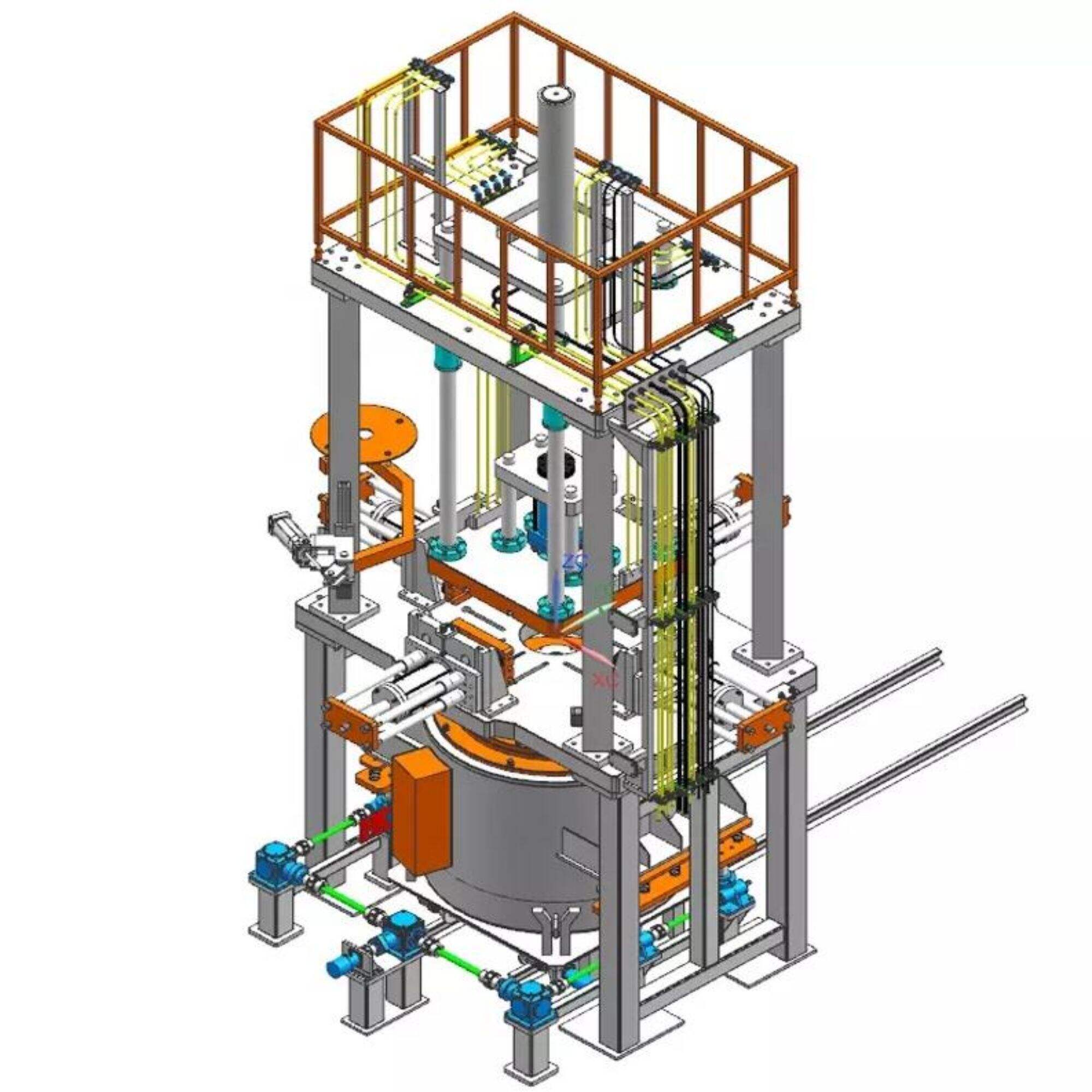

Improvements in Casting Machine Technology: Manufacturers of casting machines are vying against one another to make their products best. They intend to help the machines perform better and operate more smoothly by using high-end technology, in addition to producing highly accurate objects.

Precautions while Casting: The casting machine operates at high temperature levels hence safety precautions must be maintained when handling it. Good manufacturers always keep safety first and they have their machines equipped with several features such as temperature controls, alarms etc to ensure no accidents happen resulting in a safe working environment.

Applications of Casting Machines: The use casting machines is far and wide, some sectors they are used in include automotive sector, the aerospace and aero structuring industry as well precision mechanical engineering for jewelry production. The machines work on the other hand, making production process and efficiency more easier in manufacturing factories.

What Are The Procedures On How To Operate A Casting Machine: Turning the machine on and off is one of them. Generally, you must request the materials / desired y setting in and then heat up them at proper temperature so that way are melted totally after when building.

Importance of Casting Machines being Good In Quality : The casting machines in the jewelry industry need to be of high-quality so that you can rely on it and deliver a consistent quality output. The long-lasting machinery of manufacturers with a quality-centric approach ensures that they are reliable and versatile - able to handle multiple situations.

Service and Support: Customers demand a high level of service from casting machine investment, Top manufacturers provide the best machinery and accompany it with seamless support for ages, offering training on how to operate your machine carefully as well as necessary help if something goes wrong.

Casting machines are versatile:- The most remarkable, if not the best attractors of casting machines is versatility. They are tools that can easily produce high quality results in any of the materials they work with, and even products for professional purposes as well as more personal creations.

Final Note - Casting machines are an evident element in the processes of our manufacturing today and represent a furtherance that builders use across different types of materials. So, as the technology continues to work wonders by leaps and bounds then we can also see the endless future possibilities of casting machines for coming years.

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY