...">

×

×

Aluminium druklys vervaardiging is 'n proses om 'n metaaldeel te produseer wat noukeurig of presies ooreenstem met die vorm van die vorm. Daardeur kan ons ons die vorm voorstel van Produkte van Boqiao om 'n unieke kis te wees wat presies soos die deel vorm wat dit sal produseer. Ons begin met hierdie gietvorm en ons gooi 'n bietjie gesmeltde aluminium in. Die smelt is 'n baie heet vloeistof fase wat aluminium in bevat. Nadat ons dit gegooi het, maak dit sy weg in en verharde die aluminium om by die gietvorm te pas. As die aluminium voldoende gekoel het om te versteffig, kan ons ons gietvorm oopmaak en die gemaakte deel uitverwyder.

Een van die voordele van aluminium-stootgieting is dat baie dele baie vinnig gemaak kan word. Dit produseer een vorm van dieselfde mold, dit keer op keer gebruik. Dit laat ons toe om 'n hoop items in sowat geen tyd nie te skep, so kies vir Gravitasie drukgiet masjiene van Boqiao. Die resulterende dele, behalwe dat hulle vinnig gemaak word, is ook baie akkuraat met skoon oppervlakke. Dit wil sê, wanneer ons dele uit die gietvorm haal nadat hulle gedemold is, hoef die deel self nie te veel navorbehandeling nie. Daarom word werkers verlos van so 'n saaie werk, wat tyd en moeite spaar.

Dus presies hoekom kies soveel bedrywe vir aluminium drukgiet? Hierdie proses het verskeie voordele. Nie net is die skepping van baie dele 'n goedkoop opsie deur 3D-drukking nie, dit kan ook vinnig gedoen word. En omdat maatskappye items in groot kwantiteite moet produseer, benodig hulle 'n opsie wat sowel vinnig as koste-effektief is. Die tweede voordeel van aluminium drukgiet is dat dit gegiet kan word tot komplekse dele en met 'n hoë mate van noukeurigheid. Bedrywe wat akkurate metings en besonderhede nodig het, kies dus daarvoor. Laagdruk drukgiet masjiene van Boqiao. Die derde punt is dat die proses naby finale dele produseer, en dus slegs 'n klein afrondingswerk vereis. Dit spaar jou veral geld op jou Polishing en Paint, wat kan maak of breek die bou van sommige voertuie.

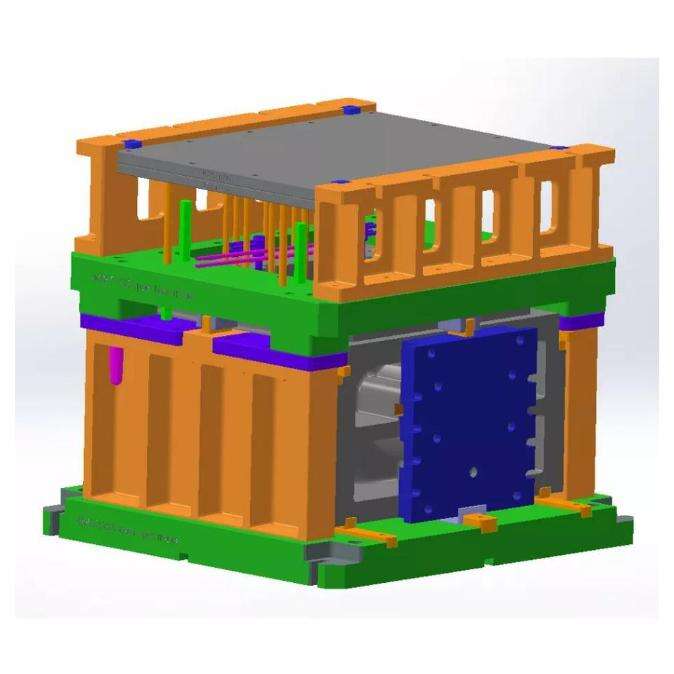

Die manier waarop 'n aluminium drukgietvorm ontwerp word, speel ook 'n kritieke rol deur die hele proses. Ons vereis dat die vorm 'n perfekte ooreenstemming wees vir die deel wat ons maak in terme van vorm en grootte. As dit nie goed aangepas word nie, sal die eindresultaat nooit goeie uitsig het nie. Verder moet daar kane deur die vorm wees om gesmelt aluminium te laat vul elke deel van die vorm. Dit lei tot 'n volledig gevulde vorm met die aluminium oorskot om hoë-kwaliteit dele te maak. Hulle word gewoonlik gemaak met harde materiaal soos staal of ander tipe langdurige stowwe. Dit behoort nie as 'n verrassing te kom nie omdat hulle die ekstreem temperature en druk moet verdure wat plaasvind in 'n gietproses, so kies vir Aluminium gietdele .

Voordeligheid van Aluminium Druklys Vervaardiging Aluminum druklys vervaardiging is baie gewild in die bedryf vir besighede om geld te spaar en meer wins te maak. Dit is vinnig, relatief goedkoop en het goeie oppervlak afwerking (dit kan sommige baie akkurate dele druk). Hierdie feit, saam met die feit dat bedrywe 'n enkele vorm kan gebruik om talries identiese dele te skep (wat verdere produksiekoste verminder), maak massaproduksiemetodes 'n aantreklike keuse en een wat baie gewild is in vandag se vervaardigingswêreld. Met ander woorde, dit laat hulle toe om meer items te produseer terwyl hulle ook minder geld uitgiet om dit te doen — 'n dubbeltjie goeie saak vir maatskappye wat kies om BQ smelttoestel .

Nanjing BoQiao Machinery Co., Ltd is 'n professionele ontwerp-, vervaardigings- en verkoopvervaardiger van verskeie gietmasjiene, aluminium spuitgietvorms en industriële oonde. Bestaande produkte wat insluit swaarweg-gietmasjiene, lae-druk-gietmasjiene, smeltovne, gloei-ovne, verhardingsovne, ouderdoms-ovne en dwars-magnetiese oonde, het 18 tipes en byna 100 soorte produkspesifikasies gevorm. Ons bied 'n reeks sleutel-in-die-hand-oplossings aan wat tegniese ondersteuning, keuse van toerusting en vervaardigingsprosesse, ontwerp, opleiding en bedryf insluit. Ons produkte skep waarde vir ons kliënte. Produkte word wyd gebruik in: elektriese kragbeskermings, motorfietsonderdele, motoronderdele, nuwe energie, elektroniese en elektriese toestelle, hoë-spannings-skerms, ingenieursmasjiene, lug- en ruimtevaartgietstukke, ventilators, huishoudelike toestelle en ander professionele gietstukproduksieondernemings.

Sedert 1999 het ons meer as 2000 eenhede vervaardig en verkoop. Die gehalte van aluminium spuitgietvorms en uitstekende dienste maak dat ons maatskappy 'n positiewe reputasie by sy kliënte geniet. Die maatskappy het sy produkte na Suid-Oos-Asië, Afrika, Suid-Amerika sowel as die Midde-Ooste versend. Kliënte was baie tevrede met die gehalte en dienste. Kliënte moet aangemoedig word om meer waarde te skep.

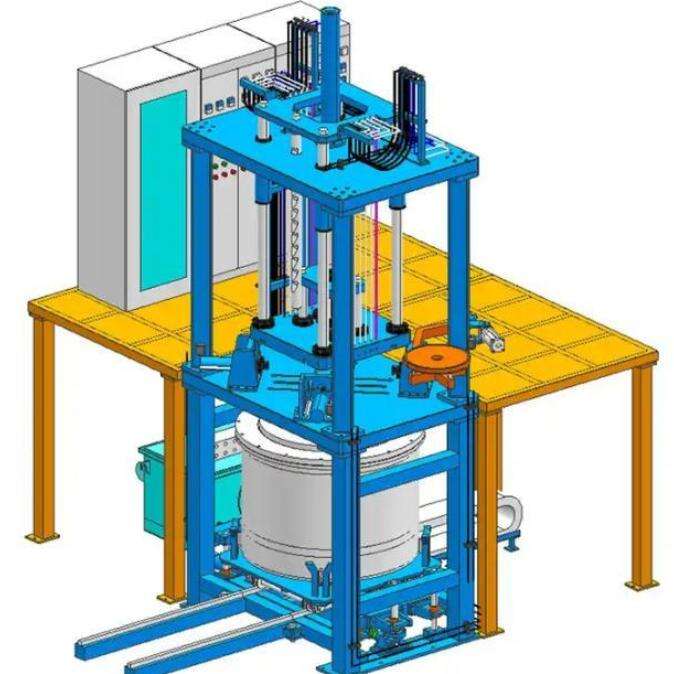

BoQiao se swaartekrag-gietmasjien vir aluminium spuitgietvorms het klein afmetings, wat dit 'n goeie keuse vir baie vervaardigingsomgewings maak. Die BoQiao swaartekrag-gietmasjien se kompakte ontwerp en hoë gehalteprestasie maak dit 'n ideale opsie vir 'n verskeidenheid vervaardigingsomgewings. Sy lae koste en langdurige vermoëns maak dit 'n uitstekende belegging vir maatskappye wat na stewige gietoplossings soek. Die masjien word deur sy kliënte hoogs gewaardeer as gevolg van sy konstante hoë gehalte, eenvoudige bedryf en onderhoud sowel as verhoogde doeltreffendheid.

Ons reis op die gebied van gietwerk het in 1979 begin met die verkoop van gietmateriale en die lê van die grondslag vir ons bedryfskundige bekwaamheid en markaanwesigheid. Oor die jare het ons langdurige verhoudings met ons kliënte opgebou deur hoëgehante produkte en uitstekende diens te verskaf. In 1997 het ons ons bedryfsaktiwiteite uitgebrei om die vervaardiging van industriële elektriese oonde in te sluit. Hierdie strategiese stap het dit moontlik gemaak vir ons om meer volledige oplossings aan ons kliënte te verskaf, wat aan hul toenemende behoeftes vir doeltreffende en betroubare verhitingsapparatuur voldoen. Ons toewyding aan innovasie en gehalte tydens hierdie tydperk het ons laat uitstaan teenoor die res van die mededingingslandskap. Teen 2002 het ons ons produkreeks uitgebrei deur in die vervaardiging van giettoerusting in te tree. Dit het ons vermoëns uitgebrei om ’n wye reeks gietoplossings van materiale tot masjinerie aan te bied, wat verseker dat ons kliënte op ons kan staatmaak vir elke aspek van gietwerk. Ons is ’n vertroude besigheidsvennoot as gevolg van ons omvangryke ervaring en kennis op die gebied van aluminium spuitgietvorms. Sedert ons begin het ons voortdurend toegewy aan kontinue verbetering en kliëntetevredenheid, wat ons gedryf het om te ontwikkel en aan te pas in ’n altyd-veranderende mark.